Composite Bearings

Scroll

/// Zero Maintenance

Lubrication is a liability.

Traditional bronze bearings require constant greasing, attract dirt, and fail catastrophically when neglected. Fritex bearings eliminate the lubricant entirely.

Self-Lubricating

PTFE liner provides permanent low friction without grease.

Indestructible

Resists shock, vibration, and extreme loads >400 MPa.

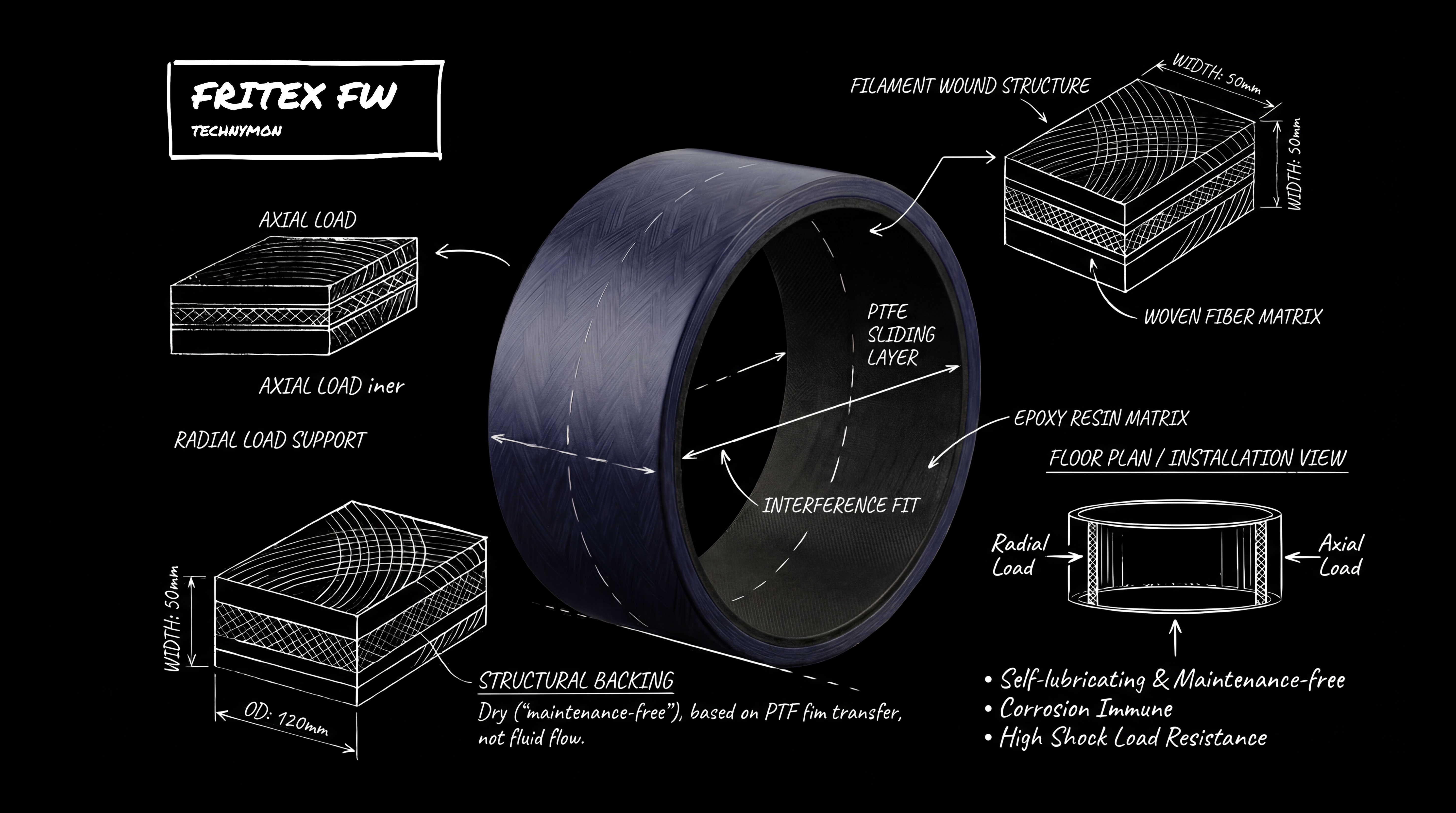

FW-Series

Filament Wound

Filament Wound fiberglass-epoxy structure. The gold standard for heavy-duty pivots.

Performance Matrix

Static Load Limit

>400MPa

Max PV (Dry)

1.8MPa·m/s

160°Celsius

0.03Coeff μ

Best Used For:

- Earthmoving Pivot points on excavators/loaders

- Marine / Subsea Winches, hatch covers, rudders

Technical Note Contains a proprietary PTFE woven fabric liner bonded to the glass-epoxy backing.

Structural Composition

View Full Diagram

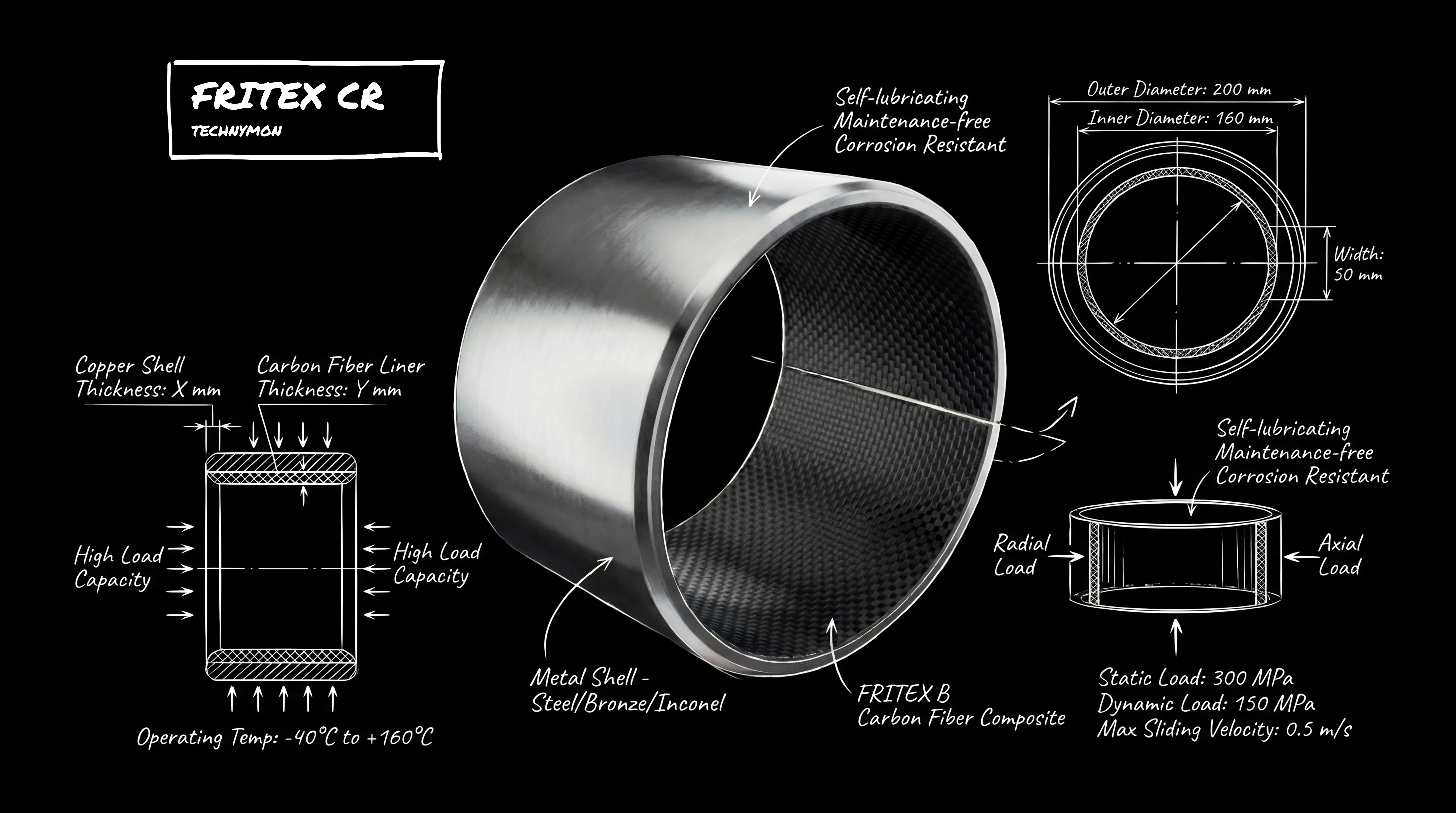

CR-Series

Metal Backed

Composite liner bonded to a metallic shell. High temperature range & precise fits.

Performance Matrix

Static Load Limit

250MPa

Max PV (Lube)

5.0MPa·m/s

280°Celsius

0.05Coeff μ

Best Used For:

- Automotive Shock absorbers, pumps, hinges

- Valves (High Temp) Fluid control up to 280°C

Note: Thin wall design allows for replacing traditional bronze bushings without resizing housing.

Structural Composition

View Full Diagram

Need specific dimensions?

We engineer custom sizes and tolerances for every application.

OPEN CATALOG